Pioneering Comprehensive Service in Smart Warehousing Solutions

Consult Our Expert for Your Tailored Solution

Solution 1

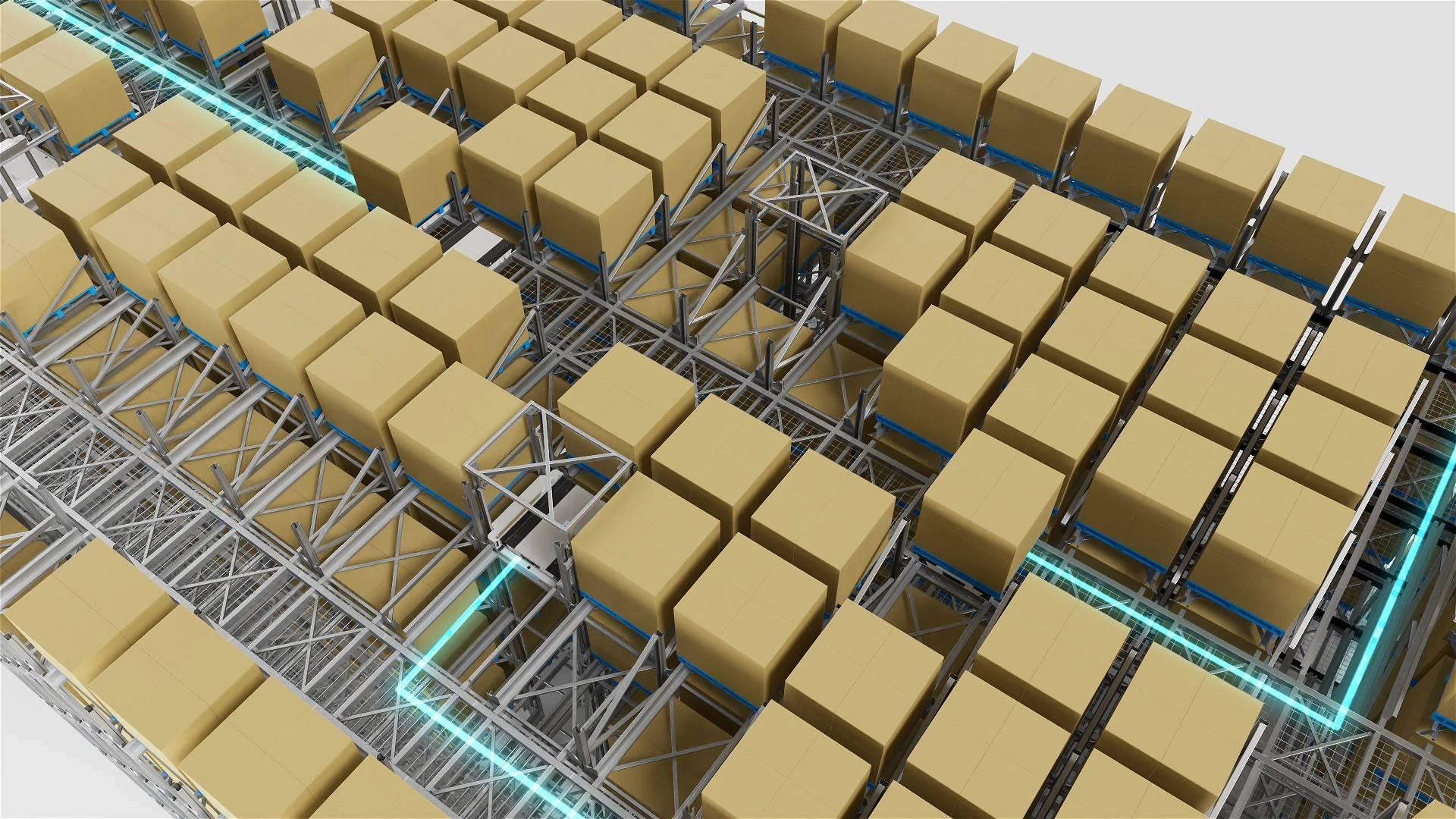

R-bot+H-bot

Six-Way Shuttle Dense Storage System

The innovative combination of R-bot four-way shuttle and H-bot vertical two-way shuttle is suitable for dense storage scenarios of whole pallet inbound and outbound or a small amount of picking inbound and outbound, with significant advantages in cost, efficiency and density. H-bot can be deployed flexibly at any position inside or outside of the warehouse, with even efficiency configuration, fast delivery and easy maintenance, which is the best choice for customers who are in pursuit of the maximum storage density and inbound and outbound efficiency.

Application Scenarios

- Warehouse Clear Height: ≤30m;

- SKU number:unrestricted;

- Storage Density: High;

- Inbound and Outbound Efficiency: High;

- Picking Efficiency: General

Applicable Industries

Food, manufacturing, cold chain logistics, energy, chemical, building materials, etc.

Composition

-

-

-

-

Solution 2

R-bot+H-bot

Six-Way Shuttle Storage & Picking System

Through the flexible deployment of H-bot vertical two-way shuttle at any position in the warehouse, R-bot four-way shuttle freely enters and exits the H-bot vertical two-way shuttle to realize cross-floor handling, and set up caching and picking positions as needed at the inbound and outbound, which is more suitable for high-density, high-throughput pallet storage and picking integrated scenarios. Compared with the traditional program, there is no need for conveyor lines in the warehouse, which greatly shortens the delivery cycle and reduces operation and maintenance costs, making it the preferred solution for pallet storage and picking scenarios in the market today.

Application Scenarios

- Warehouse Clear Height: ≤30m;

- SKU Number: Many;

- Storage Density: High;

- Inbound and Outbound Efficiency: High;

- Picking Efficiency: High;

Applicable Industries

E-commerce, Retail, 3PL,etc.

Composition

-

-

-

-

Solution 3

U-bot

Narrow aisle storage system

Application Scenarios

- Warehouse Clear Height: ≤10m;

- Number of SKUs: Relatively more;

- Storage Density: Relatively high;

- Inbound and Outbound Efficiency: Relatively high;

- Picking Efficiency: Relatively high

Applicable Industries

3PL, Retail, Manufacturing, Food, E-commerce, Cold Chain, Energy, Apparel, etc.

Composition

-

-

-

-

Solution 4

U-bot + AMR Narrow Aisle Picking System

The Narrow Aisle Picking System, featuring U-bot + AMR , facilitates efficient collaborative operations such as “high-rack storage and low-rack buffering” and “high-rack storage and low-rack picking.” It can be integrated with multi-functional workstations to accommodate the picking and outbound requirements of a wide range of item sizes, from large to small. The system can also connect with production lines via AMR to flexibly adapt to various operational scenarios. The PTP Smart Warehouse Software enables multi-vehicle smart scheduling, significantly enhancing overall efficiency.

Application Scenarios

- Warehouse Clear Height: ≤10m;

- Number of SKUs: Many;

- Storage Density: Relatively high;

- Inbound and Outbound Efficiency: High;

- Picking Efficiency: High

Applicable Industries

E-commerce, manufacturing, shoes and clothing, etc.

Composition

-

-

-

-

-

Comparison of the Five PTP Storage and Picking Solutions

R-bot+H-bot

Six-Way Shuttle Dense Storage System

Number of SKUs: Relatively small

Storage density: High

Inbound and outbound efficiency: High

Picking efficiency: Average

R-bot+H-bot

Six-Way Shuttle Storage & Picking System

Number of SKUs: Relatively large

Storage density: High

Inbound and outbound efficiency: High

Picking efficiency: High

U-bot

Narrow Aisle Storage System

Number of SKUs: Many

Storage density: Relatively high

Inbound and outbound efficiency: Relatively high

Picking efficiency: Relatively high

U-bot+AMR

Narrow Aisle Picking System

Number of SKUs: Many

Storage density: Relatively high

Inbound and outbound efficiency: High

Picking efficiency: High

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955